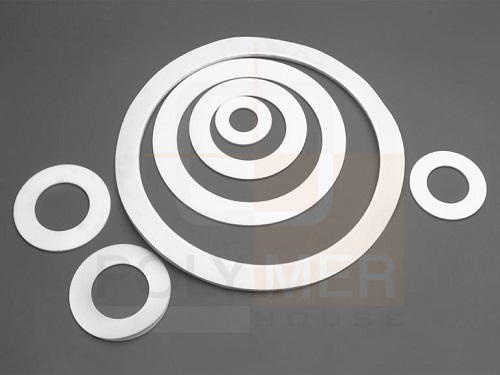

Spiral Wound Gaskets

Product Details:

- Vaccum Range Full vacuum to high pressure

- Temperature Resistance Up to 550C

- Medium Steam, oil, gas, acids, solvents, water, etc.

- Gasket Coefficient 0.400.70 (Y)

- Pressure Resistance Up to 250 bar (25000 KPa)

- Standard ASME B16.20 / API 601, DIN, JIS, or custom

- Shape Round

X

Spiral Wound Gaskets Product Specifications

- Available (commonly SS304, SS316, or carbon steel)

- Up to 550C

- Available (carbon steel, SS304, SS316, or coated metals)

- Steam, oil, gas, acids, solvents, water, etc.

- Full vacuum to high pressure

- 3.2 mm, 4.5 mm, 6.4 mm, Custom sizes available

- Range from 1/2 to 60 (15mm to 1500mm) or customized as per specification

- ASME B16.20 / API 601, DIN, JIS, or custom

- Up to 250 bar (25000 KPa)

- Round

- 0.400.70 (Y)

- Petroleum, chemical, power generation, pulp & paper, marine, and general industry pipe flanges and heat exchangers

Spiral Wound Gaskets Trade Information

- Cash in Advance (CID), Cheque, Cash Advance (CA)

- As per customer requirement.

- Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Customized.

- Australia, Eastern Europe, Africa, Central America, Middle East, South America, Western Europe, Asia, North America

- All India

Product Description

We are ranked as one of the leading suppliers of Spiral Wound Gaskets. Our stock is made using quality materials that make these chemical resistant in quality. Available in the dimensions of 15 mm-3500 mm, these gaskets are manufactured with the international standards such as api 601, asme b16. 2, asme 16. 47 a & b series, din and jis, bs. Additionally, our Spiral Wound Metallic Gaskets is delivered at nominal prices.

Key Features:

- Effective for joints

- Ensure excellent sealing

- Rust proof finish

Further Details:

The fillers used in the gaskets are graphite, asbestos & PTFE. The stripes are wound evenly in a concentric spiral under stress.

Robust Design for Critical Applications

Spiral wound gaskets deliver a reliable seal even in challenging environments. Their combination of metal windings and filler materials ensures excellent recovery and resilience against thermal cycling, vibration, and high-pressure conditions. Custom sizing and ring materials make them adaptable to a wide range of process requirements in both standard and highly specialized applications.

Engineered for Industry Standards and Versatility

Manufactured to meet ASME B16.20, API 601, DIN, and JIS standards, these gaskets guarantee compatibility with global industrial systems. The choice of thickness, sizes, and materials allows for precise matching with project specifications, ensuring long service life and optimal equipment efficiency. Custom shapes and sizes further enhance their utility across industries.

FAQs of Spiral Wound Gaskets:

Q: How are spiral wound gaskets installed on pipe flanges and heat exchangers?

A: Spiral wound gaskets are placed between flange faces or in the seating area of heat exchangers. It is crucial to choose the correct size and specification, align the gasket properly, and tighten the bolts uniformly. This process ensures a secure seal that withstands thermal, pressure, and vibration stresses commonly encountered in industrial systems.Q: What types of media can spiral wound gaskets effectively seal against?

A: These gaskets are suitable for sealing a variety of media, including steam, oil, gas, acids, solvents, and water. Their robust construction and material selection enable reliable performance across petroleum, chemical, power generation, pulp and paper, marine, and other general industry applications.Q: When should I select a custom size or different thickness for a gasket?

A: Custom sizes or non-standard thicknesses are typically chosen when equipment dimensions or operating conditions do not match common specifications. Factors such as flange compatibility, process pressure, temperature, and medium type influence whether a customized gasket will ensure optimal sealing performance and equipment safety.Q: Where are spiral wound gaskets commonly used in industrial settings?

A: Spiral wound gaskets are widely used in pipe flanges, heat exchangers, pumps, and valves across industries such as petroleum refining, chemical manufacturing, power plants, pulp & paper production, marine vessels, and general mechanical piping systems where high pressure and temperature resilience are required.Q: What is the benefit of having inner and outer rings on a spiral wound gasket?

A: Inner and outer rings enhance gasket stability, correct alignment, and prevent blowout under high-pressure or vacuum conditions. The rings also help center the gasket during installation and provide additional protection against aggressive process media, improving gasket longevity and reliable sealing over time.Q: How do spiral wound gaskets handle fluctuating temperatures and pressures?

A: Thanks to their layered construction and the resilience of metal windings, spiral wound gaskets absorb mechanical stresses from thermal cycling and pressure changes. Their design maintains a consistent seal, minimizing leakage risks even as operational conditions fluctuate.Q: What standards do these gaskets meet and why is this important?

A: These spiral wound gaskets comply with ASME B16.20, API 601, DIN, and JIS standards, ensuring compatibility with internationally recognized equipment and requirements. Adherence to these standards guarantees a high level of safety, performance, and interchangeability in industrial systems worldwide.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email